What We Do

Overview

- The Right Team: Our team is comprised of former operators, maintainers, design engineers, production subject matter experts, and seasoned defense industry professionals from many of the largest Primes and several innovative defense tech startups

- Subject Matter Expertise: We have subject matter expertise across design engineering, prototyping, specialized manufacturing, producibility, capability installation and post installation services. We’ve been down range and executed in the most challenging conditions

- Mission-Driven Innovation: We focus on modular design, rapid prototyping, and lean manufacturing principles to develop scalable solutions tailored to accelerate platform readiness and sustainment. Every project is approached with a warfighter-first mindset, ensuring relevance and readiness in contested environments

- Trusted by Tier-One Primes: Recognized by industry leaders such as Northrop Grumman and Raytheon, Apogee Worx, LLC delivers complex kitting, certified copper and fiber optic harness assemblies and diverse support equipment for critical aerospace platforms. Our past performance reflects a proven track record of dependability and technical competence

- Agility with Precision: As a nimble, veteran-led small business, Apogee Worx offers responsive program execution with a commitment to precision manufacturing and mission assurance. We adapt quickly to shifting customer demands while upholding the highest standards in quality and compliance

- The Right Infrastructure: Secure 33,000 sqft environmental controlled and monitored manufacturing facility. Rapid Agile Modular Manufacturing Process (RAMMP) enabled production & robust supply chain across proven manufacturing domains. Expansion options in place to support increased demand

- The Right Supply Base: Apogee Worx, LLC is at the forefront of America's re-industrialization, leveraging a deeply rooted and agile supplier network specializing in Aerospace & Defense manufacturing. Our supplier intimacy ensures rapid scalability, reduced lead times, and mission-ready solutions delivering unmatched value to customers seeking reliability, resilience, and U.S.-based production strength

Key Capabilities

At Apogee Worx, LLC, our core strength lies in our ability to deliver complex capability integration across diverse weapon systems and mission support equipment. Our proprietary Rapid Agile Modular Manufacturing Process (RAMMP) integrates engineering, production, and supply chain responsiveness into a single, agile methodology. This approach has enabled us to deliver 196 technical solutions over the past four years, with a 98.5% acceptance rate, addressing critical issues like dimensional tolerance conflicts, parts obsolescence, and design discrepancies.

Our capabilities cover the full spectrum of defense modernization—from design engineering and rapid prototyping to manufacturing and post-installation support. We specialize in the integration of platform-agnostic sensors and effectors across both airborne and ground-based systems, as well as mission support equipment.

Engineering

- Manufacturing Solutions Engineering

- Manufacturing Readiness Assessments

- Process Engineering

- TDP Verification & Validation

- Systems, Electrical, Mechanical, Structural

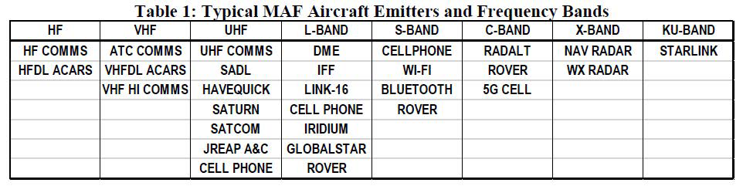

- EW/RF/Aeronautical Engineering

- Sensors, Processing, PVI Development

- Communications & Data Link Integration

Test & Support

- Test House Collaboration

- Test Plan Development

- On-Aircraft Test Support

- Analysis & Reporting

Services

- Depot Level Weapon System Modification and Installation

- On-site Customer Technical Support

- Contractor Field Teams

Manufacturing

- Kitting & Serial Production

- Precision Metal Manufacturing Assembly

- Coatings & Conversion Coatings

- Additive Manufacturing

- Digital Light Processing Resin 3d Printing

- Wire Harness Manufacturing

- Laser Wire Marking

- Robust selection of MIL-DTL-38999 contact termination tooling

- Semi-Automated Wire Stripping (Mechanical & Thermal)

- Wire Board 1 to 1 Technical Drawing Scaling

- On-site Large Format Mylar or Paper Printing

- HIPOT Testing

- Cirris CH2 High Voltage Harness testing

- Time Domain Reflectometer (TDR) testing

- Thermal Transfer Wire Label Printing

- Potting & Custom Potting Molds

- Fiber Optics Harness Manufacturing

- On-site Overbraiding

- Standard selection of MIL-PRF-29504 termini terminations tools that support MIL-DTL-38999, ARINC 801 and 806 style connectors

- Optical Time Domain Reflectometer (OTDR) testing

Cage Code: 7KKF3, UEID: CK7GKW3KBA9, NAICS Codes:

- 334513 - Instruments and Related Products Manufacturing

- 335931 - Cable Manufacturing

- 336411 - Aircraft Manufacturing

- 336413 - Other Aircraft Parts and Aux Equip Manufacturing

- 541330 - Engineering Services (Primary)

- 541370 - Surveying and Mapping Services

- 541519 - Other Computer Related Services IT Value Added Resellers

- 541611 - Administrative Management and General Management Consulting Services

- 541614 - Process, Physical Distribution, and Logistics Consulting Services

- 541715 - R&D (Phys, Eng, & Life Sciences). Aircraft, Aircraft Parts and Aux, Guided Missiles, Propulsion Units and Parts

- 334419 - Other Electronic Component Manufacturing

- 335311 - Power, Distribution, and Specialty Transformer Manufacturing

- 336419 - Other Guided Missile and Space Vehicle Parts and Auxiliary Equipment Manufacturing

Our Mission

As a trusted partner, we deliver agile capability integration and manufacturing across airborne, ground based and mission support equipment to enable complex weapon system modernization for our customers and ultimately the warfighter.

Lifecycle Accountability

From design to certification, you have one accountable partner—Apogee Worx, LLC.

Vision to Transform

Founded with a vision to transform defense manufacturing, Apogee Worx, LLC is a trusted partner to the Department of Defense, prime contractors, and commercial clients. Our mission is to deliver agile, innovative solutions that ensure mission relevance in an evolving battlespace. With a focus on aerospace and defense, we combine decades of experience with a forward-thinking approach to tackle the most complex integration challenges.

Our team’s expertise spans design engineering, prototyping, capability installation, and post-installation services, making us a critical bridge between capability providers and end-users. We pride ourselves on our Rapid Agile Modular Manufacturing Process (RAMMP), which has revolutionized project timelines and cost efficiency. For instance, our work on the KC-135 LAIRCM program cut lead times by 80%, delivering scalable, cost-effective solutions.